Soooo impressive. Did the whole setup survive all this time or just the machine itself?

- 5 Posts

- 40 Comments

1·1 month ago

1·1 month agoCheers, made an account yesterday night and will probably sink way too much time into that rabbit hole :)

So far it looks really well thought through.

Also the idea with the comic cardboards is really nice. Found an offer that comes with clips already. Might work well with the boxes I use currently as well, as it allows for quicker access to sth that’s sitting at the bottom without fear of having to refold half the stash

1·1 month ago

1·1 month agoI found that left over Popeline makes great pocket fabric, but there’s only so many pockets you sew into your clothes…

3·1 month ago

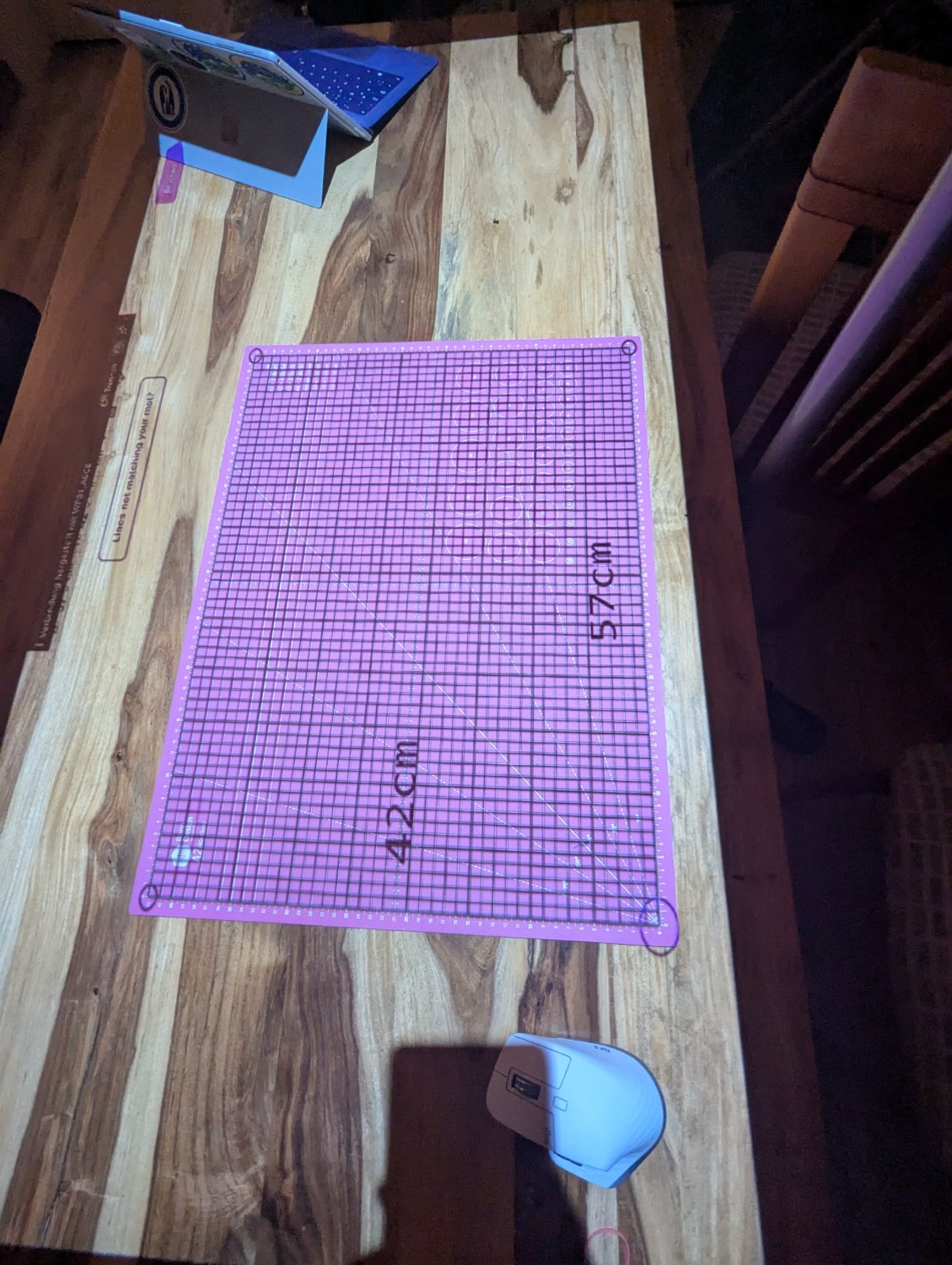

3·1 month agoOne solution I thought of was marking 2m x 2m points on the floor when taking the photos. That way I can stretch it afterwards on the pc to understand whether a new pattern can still fit on a used piece of fabric.

My go to for a ready to follow experience where I don’t need to think twice on how the next step works is pattydoo. German tailor who makes great instruction videos and has fair prices (most pdf are 4€). She has good beginner friendly patterns

Even works when you get your pattern from somewhere else (use it in combination with freesewing.org a lot, making a pattern there that fits me 1:1 then go to pattydoo to see how to fiddle in the zipper on the jeans etc)

1·1 month ago

1·1 month agoHey, I use jersey with high cotton content (typically 95% cotton 5% elastan) for briefs.

You can make higher quality briefs from merino (good for long hiking days for example), but also more expensive and not everyone likes woolen underwear.

Sewing jersey is a bit more tricky, as it tends to roll up at the edges (i.e. Pinning it takes a bit longer).

I like the shorts pattern from pattydoo. Was one of the first things I made myself and still make a new pair on occasion. Shorts fabric is typically popeline, but saw people use muselin fabric as well. Soft fabric is comfier, but stiffer fabric can be nice for really hot days. Linen and cotton both make good shorts :)

If you have any more questions feel free to reach out.

Have fun with your new machine!

8·2 months ago

8·2 months ago

the Beamer points nearly straight down. Combined with the open-source software patternprojector it took less than a minute to calibrate the projection perfectly.

Image of a projected pattern, in this case the Cornelius trousers from freesewing.org.

2·2 months ago

2·2 months agoThe MacGyver variant took some time to setup, but if you can find a way to permanently mount it as I had in my old flat then it’s actually very quick to start :)

Still I get the reluctance. I was at the point where I thought of getting a printer and then decided for the projector instead. It’s faster and produces less waste (speaking more of the fabric than the paper here).

If you got a dedicated workshop (little bit of envy here, I’d love that) then you could just mount it to the ceiling, thereby it takes up no additional space

1·2 months ago

1·2 months agoSmart, with the hot iron you immediately seal the cut and it can’t have threads falling out any more. I’ll keep that in mind if I ever do another batch of bivy bags

1·2 months ago

1·2 months agoThat’s pretty awesome, your light table means you don’t have the hand shadow on the projection, but also only works on cloth that let’s through light. what material do you use for the top so that your can cut on it and have the light shine through?

1·2 months ago

1·2 months agoHow do you then get it from the paper on the fabric?

2·2 months ago

2·2 months agoYou mean sth like this?

Didn’t know that even existed but your suggestion is genius! That’s fixing the problem so much better than anything I came up with 😍. Ordered, incl. a mount for the Beamer. Will post an update once it’s here

2·2 months ago

2·2 months agoWhat’s really nice from my POV is that they have the github repo there for self hosting, but also got a public instance run by the initiator for all those who - like me - are too stupid to set up their own infrastructure and rather want to spend time on their sewing machine than in front of a display

1·2 months ago

1·2 months agoI’m tending to a slide and lock solution currently. Would mean some 3d printing most likely but would allow to unmount the projector when not in use (the room I use is our living room, wild cables running up the wall and a projector permanently sticking from the ceiling don’t look very good)

Hmm, if we’re generous, the volume is around 8l, the cloth weighs 38g, difference in density is 1kg/m3 between air and helium.

1000g\m3*0.008m3 = 8g lift VS 38g mass. This won’t take off but that wasn’t the intention here :)

3·2 months ago

3·2 months agoMade trousers that way and will make a copy of my SIL’s favorite onesie the same way this spring (it’s seen too much love, so time for a new one)

3·2 months ago

3·2 months agoAh, now that first comment makes a lot more sense.

As for your second problem, did you ever hear of freesewing.org? It’s an open source parametrized pattern generator. (can be very frustrating though if you spend 2 days on a buttoned shirt to find that you took a wrong measurement and your shoulders are too tight now) but with your background this could be the way to go. Goes very well with the projector too.

2·2 months ago

2·2 months agoYou’re welcome :)

Ah my bad, lost in translation. I do the shoulders exactly like you suggest. The problem was the lower end of the arm where the hand sticks out. I now do them also like you suggested, with the side+underarm seam being the last one I close on the feature